Organic Vapor Phase Deposition for Optoelectronic Devices

The

growth of molecular organic thin films by the process of organic vapor phase

deposition (OVPD) was initiated by Professor Steve

Forrest OVPD transports organic molecules to a

cold substrate by a hot inert carrier gas. It has proven useful for the

deposition of organic semiconductors, and is capable of patterned growth with

micron resolution. Professors Benziger and Forrest collaborated to

engineering the process for a scalable continuous process. Most recently, Profs. Forrest and Benziger have

demonstrated direct printing of molecular organic materials based on a new

method of growth, organic vapor jet printing (OVJP),

where molecules are carried to the substrate by a hot carrier gas jet.

The diameter of the deposit is limited by the gas jet dynamics and nozzle dimensions,

and is capable of generating patterns ~500nm.

The context and concept of OVPD: Background and Related Work

Typically, thin (<100nm) film

molecular organic electronic devices such as organic light emitting devices (OLEDs), are grown by vacuum thermal

evaporation (VTE), permitting the high degree of

purity, pattern, and structural control needed for high performance operation.

However, control of film thickness uniformity and dopant

concentrations over large areas needed for many applications can be difficult

when using vacuum evaporation – currently the most commonly used technique for

the deposition of organic molecular solids. In addition, a considerable

fraction of the evaporant coats the cold walls of the

deposition chamber; over time, inefficient materials use results in a thick

coating which can flake off, leading to particulate contamination of the system

and substrate. The potential throughput for vacuum evaporated organic

thin film devices is low, resulting in high production costs. Low

pressure organic vapor phase deposition (OVPD) has

been demonstrated as an alternative technique that significantly improves

control over doping, and is adaptable to rapid, particle-free, uniform

deposition of organics on large-area substrates.

Carrier Gas Flowrate ( )

Kinetic

Equilibrium

Temperature (Tcell)

Equilibrium

T

Constant

a)

b)

Fig.

1: (a) Schematic of the OVPD process, (b)

the regimes of OVPD growth.

In OVPD, the

organic compound is thermally evaporated into a diluting, non-reactive gas

stream, and then transported in a hot-walled reactor toward a cooled substrate

where condensation occurs (see Fig. 1). Flow

patterns may be engineered to achieve a substrate-selective, uniform

distribution of organic vapors, resulting in a very uniform coating thickness

and minimized materials waste. Virtually all of the organic materials

used in thin film devices have sufficiently high vapor pressures to be

evaporated at temperatures below 400°C, and then be transported in the vapor

phase by an inert carrier gas such as nitrogen. This allows for

positioning of evaporation sources outside of the reactor tube spatially separating the functions of evaporation and

transport, thus leading to precise control over the deposition process.

To grow doped films with uniform composition across the entire substrate area,

the component streams must be mixed prior to deposition. By carrying out

the process at reduced pressure, gas diffusivity is increased, improving rates

of mass transfer between component streams and to the substrate, which promotes

thickness uniformity of the deposited films.

In vapor phase deposition, organic molecules are carried out

of the source cell at a rate, r, proportional to the volumetric flow velocity

of the carrier gas,  ,

and the concentration of organic vapors in the evaporation cell, Porg/RTcell:

,

and the concentration of organic vapors in the evaporation cell, Porg/RTcell:

(1)

(1)

Here,

Tcell is the evaporation cell temperature,

Porg is the actual vapor

pressure of the organic material, and R is the universal gas constant. It

can then be shown[7] that the partial pressure of

the organic evaporant in the carrier gas stream is

given by:

,

(2)

,

(2)

where kevap and kcond are kinetic factors proportional to the

rates of evaporation and condensation, respectively, and  is

the equilibrium vapor pressure of the organic material. As Eq. (2) and Fig. 1b show, at

high evaporation temperatures and sufficiently low gas flow rates, the vapor

and solid in the source region equilibrate (i.e.

is

the equilibrium vapor pressure of the organic material. As Eq. (2) and Fig. 1b show, at

high evaporation temperatures and sufficiently low gas flow rates, the vapor

and solid in the source region equilibrate (i.e.  ),

and the concentration of organic exiting the source is constant. The

resulting flux of organic species in the “equilibrium” evaporation regime is

thus proportional to the vapor pressure and the carrier gas flow rate. At

the other extreme of low evaporation temperatures and high gas flows, the

carrier gas sweeps the organic out of the source region as quickly as it

evaporates, forcing the system away from equilibrium. In this case, the

concentration of organics in the gas stream is proportional to revap and inversely proportional to

),

and the concentration of organic exiting the source is constant. The

resulting flux of organic species in the “equilibrium” evaporation regime is

thus proportional to the vapor pressure and the carrier gas flow rate. At

the other extreme of low evaporation temperatures and high gas flows, the

carrier gas sweeps the organic out of the source region as quickly as it

evaporates, forcing the system away from equilibrium. In this case, the

concentration of organics in the gas stream is proportional to revap and inversely proportional to  .

In the “kinetic” evaporation regime, therefore, the flux of organic material

leaving the source is independent of the carrier gas flow. Figure 1b

illustrates how the vapor pressure of organics exiting the source varies with

temperature and flow rate for both the equilibrium and kinetic evaporation

regimes. It will become apparent below that the ability to operate OVPD

in either of these two regimes provides unprecedented

opportunities to control the structure and quality of the thin film.

.

In the “kinetic” evaporation regime, therefore, the flux of organic material

leaving the source is independent of the carrier gas flow. Figure 1b

illustrates how the vapor pressure of organics exiting the source varies with

temperature and flow rate for both the equilibrium and kinetic evaporation

regimes. It will become apparent below that the ability to operate OVPD

in either of these two regimes provides unprecedented

opportunities to control the structure and quality of the thin film.

As

in vacuum evaporation, the equilibrium vapor pressure of the organic material

depends exponentially on cell temperature, Tcell.

The partial pressures of the evaporant leaving the

source region are:

(3)

(3)

,

(4)

,

(4)

where DHvap is the enthalpy of vaporization specific to

each compound, and superscripts “eq” and “kin” denote

equilibrium and the kinetic evaporation modes, respectively.

Hence,

a significant difference between vacuum evaporation and OVPD is that in the

latter process, the rate of introduction of the organic species onto the

substrate is determined by both source temperature (where the

rate is exponential with temperature) and gas flow rate,  (providing

linear control of source introduction, c.f. Eq. (5)).

Hence, we have shown doping of one or more organic species into a host thin

film is far more controllable than using simple temperature control

characteristic of vacuum deposition. We have demonstrated very low and

controllable doping concentrations of <0.5% of

a red lumophore, DCM2, doped into an Alq3

host.

(providing

linear control of source introduction, c.f. Eq. (5)).

Hence, we have shown doping of one or more organic species into a host thin

film is far more controllable than using simple temperature control

characteristic of vacuum deposition. We have demonstrated very low and

controllable doping concentrations of <0.5% of

a red lumophore, DCM2, doped into an Alq3

host.

Temperature

probes

To

Pump

Rotating

cooled holder

Thickness

monitor

4-zone heater

Glass

chamber

4

source

barrels

Mechanical

Shutter

Carrier

Gas

Inlets

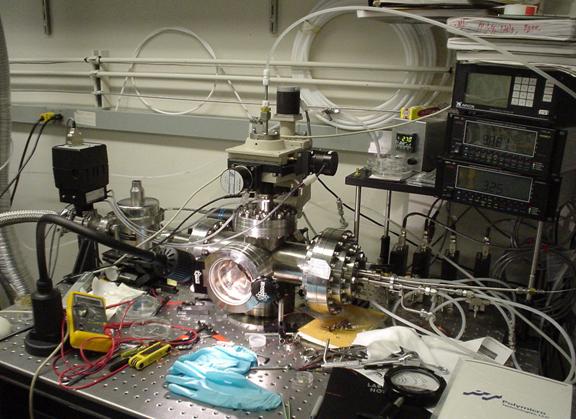

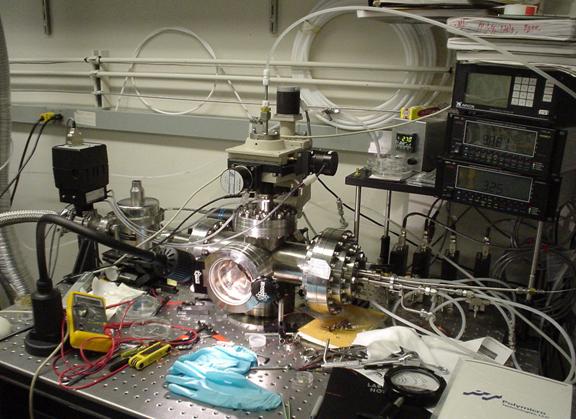

Fig.

2: Schematic of original OVPD system. Photo shows the system with the clam-shell

furnace open to show a clean glass tube and substrate holder after >150

growth runs

Organic Vapor Jet Printing (OVJP)

OVJP

is a natural extension of OVPD deposition through shadow mask apertures, where

organic patterns are individually deposited through a small orifice onto a

substrate located directly beneath a nozzle. The nozzle itself is fed by

a vapor of organics and a carrier gas, thereby transporting a small amount of

material in a spatially confined area. Similar to ink jet printing,

the deposition of individual pixels on extended plastic substrates continuously

deployed in close proximity to the localized jet of gas can be achieved.

It differs substantially from solution-based ink jet printing of polymers,

however, in that the solvent in OVJP is a gas. Hence, it is easily

volatilized during growth to leave a uniform film of the desired organic.

This process, invented at Princeton,

has the possibility of revolutionizing the growth of small molecule organic

thin films by rapidly and simply depositing ultrasmall

(nanometer scale) patterns of organic thin film

materials or precursors. Like OVPD, the process works by passing a heated

gas through a hot organic source powder or liquid. The gas then entrains

the molecular species, carrying it through a valved

nozzle to a cooled, horizontally translating substrate where the material

deposits. The ultimate deposit resolution achievable by this method

is determined by the distance from the nozzle to the substrate, the gas flow

velocity, the background pressure, temperature, and the diameters of the

orifice and the tip. The practical limits to these dimensions are ~500nm,

using an orifice with micropores. Below this

diameter, the gas viscosity will limit the transport of material through the

orifice.

mixing

chamber

N2

N2

N2

Schematic of the OVJP process. Carrier gases pick up

the organic vapor and direct the organic onto the substrate through a

nozzle. The higher mass organic retains its forward momentum towards the

substrate and is kept collimated to provide good resolution.

Organic Vapor Jet Printing Apparatus.

1.5mm

HPTM

2250 ColorJet

Ink

Jet Printer

SPTM

2000

Organic

Vapor Jet Printer

Example of the resolution of OVJP. The resolution of

the prototype system is ~ 1200 dpi.

OVJP

can print thin film transistors without the need for a vacuum system.

![]() ,

and the concentration of organic vapors in the evaporation cell, Porg/RTcell:

,

and the concentration of organic vapors in the evaporation cell, Porg/RTcell:![]()

,

,

![]() is

the equilibrium vapor pressure of the organic material. As Eq.

is

the equilibrium vapor pressure of the organic material. As Eq. ![]() )

)![]() .

In the “kinetic” evaporation regime, therefore, the flux of organic material

leaving the source is independent of the carrier gas flow. Figure 1b

illustrates how the vapor pressure of organics exiting the source varies with

temperature and flow rate for both the equilibrium and kinetic evaporation

regimes. It will become apparent below that the ability to operate OVPD

in either of these two regimes provides unprecedented

opportunities to control the structure and quality of the thin film.

.

In the “kinetic” evaporation regime, therefore, the flux of organic material

leaving the source is independent of the carrier gas flow. Figure 1b

illustrates how the vapor pressure of organics exiting the source varies with

temperature and flow rate for both the equilibrium and kinetic evaporation

regimes. It will become apparent below that the ability to operate OVPD

in either of these two regimes provides unprecedented

opportunities to control the structure and quality of the thin film.![]()

![]() ,

,

![]()